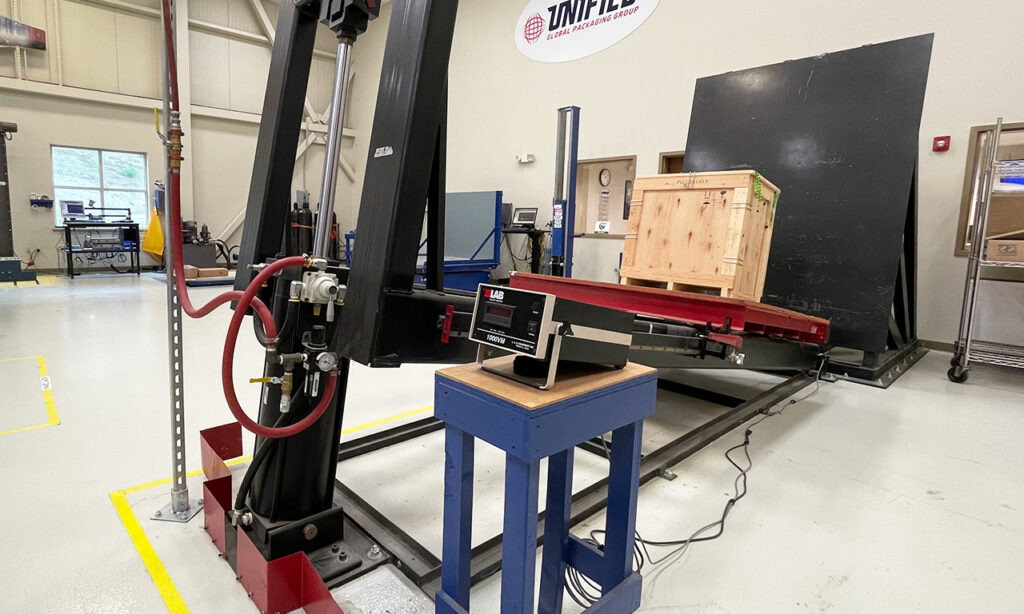

Drop & Shock Testing

Packaging must withstand the sudden impacts and shocks that occur during handling, shipping, and storage. Our drop and shock testing services simulate these real-world conditions to ensure your products arrive safely and intact.

Benefits of Drop & Shock Testing

- Prevents product damage during transit

- Reduces returns and warranty claims

- Ensures compliance with industry and retailer standards

- Improves customer satisfaction and brand reputation

ASTM D5276 – Free-Fall Drop Test

Evaluates the ability of packages (up to 110 lbs) to withstand sudden shocks from manual handling. Packages are dropped from specific heights based on weight:

- Up to 20 lbs: 30 inches

- 21–40 lbs: 24 inches

- 41–60 lbs: 18 inches

Drops are performed on faces, edges, and corners to identify weak points. Typically, five drops are conducted in different orientations.

ASTM D5487 – Simulated Drop Using Shock Machines

ISTA Series – Comprehensive Transit Simulation

ISTA protocols combine drop testing with vibration and compression to replicate full shipping journeys:

- ISTA 1A: Basic integrity test for packages ≤150 lbs

- ISTA 2A: Partial simulation test for packages ≤150 lbs, including drops, vibration, and compression

- ISTA 3A: Advanced simulation for packaged products shipped through complex supply chains