Beauty in the Breakdown: Turning Waste into Protection

At UGPG2, we believe in giving waste a second life; since 2011, we’ve been re-processing post-industrial recycled content (PIR) fiber into high-performance molded pulp that protects your products and the planet. Every tray, insert, and structural form we mold is proof that sustainability and precision can, and should, go hand in hand.

Designs That Support Circularity

Our molded pulp is primarily produced from PIR Double-Lined Kraft (DLK) and newsprint. Two renewable and abundantly available low-cost materials in the market. When the economics align, we go even further, incorporating local agricultural byproducts like bamboo, bagasse, and wheat straw to support regional supply chains and circular economies.

Why it matters:

- Reduces waste to landfill by making use of materials already in circulation

- Offers customers a cost-effective alternative

- Designed with sustainability in mind

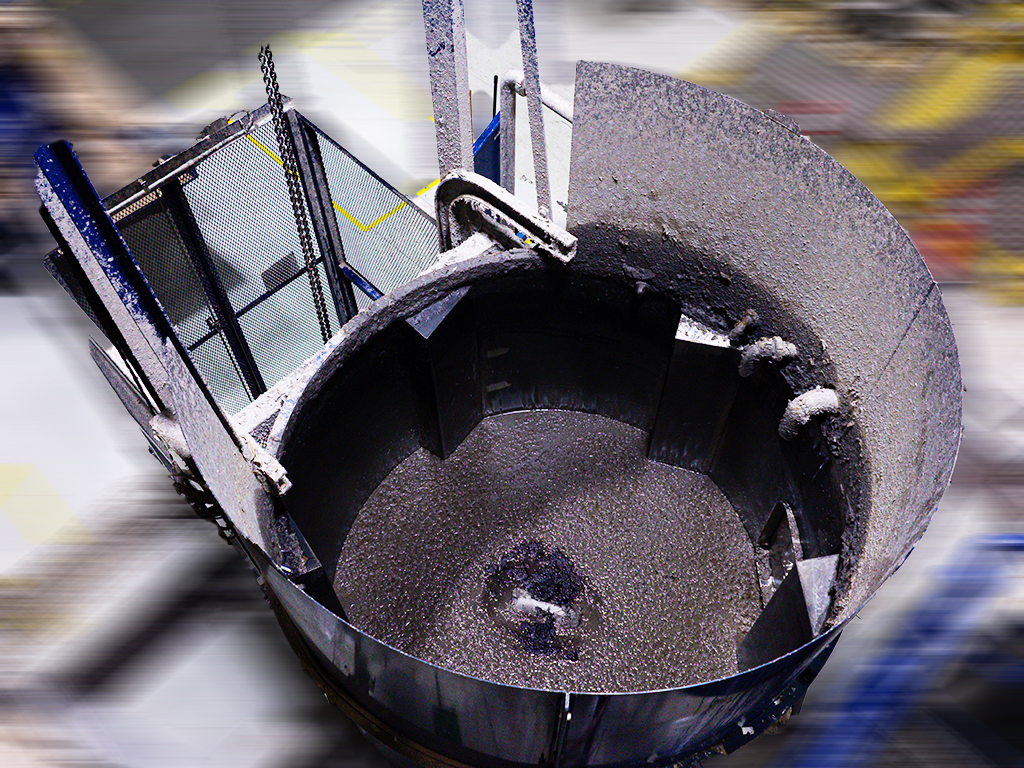

From Waste to Performance Packaging

With in-house pulp molding capabilities and vertically integrated recycling, we control every process step. That means higher consistency, better material performance, and a tighter grip on cost and quality.

What makes UGPG different:

- Fully vertically integrated from material sourcing to final product

- In-house pulp production and molded fiber manufacturing

- Ability to close the loop by using scrap materials as our inputs.